| Sign In | Join Free | My ledscreensign.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ledscreensign.com |

|

Brand Name : WINCOO

Model Number : MSHW

Certification : CE

Place of Origin : CHINA

MOQ : 1 unit

Price : USD 5000~12000

Payment Terms : L/C,D/A,D/P,T/T,Western Union

Supply Ability : 230 Set/Year

Delivery Time : 45 working days

Packaging Details : Export package

Model NO. : MSHW

Keywords : Tank Vertical Welding Machine

Plate Thickness : 8~45mm

Plate Material : Carbon Steel, Stainless Steel

Welding Process : Saw

Transport Package : Container

Specification : SGS, ISO9001, CE

Trademark : WINCOO

Origin : Nanjing, China

HS Code : 851531900

Cooling Way : Water Cooling

Control : Semi-Automatic

Style : Hanging

Frequency Range : Intermediate Frequency

Electric Current : Inverter

Type : Continuous Seam Welder

Customization : Available | Customized Request

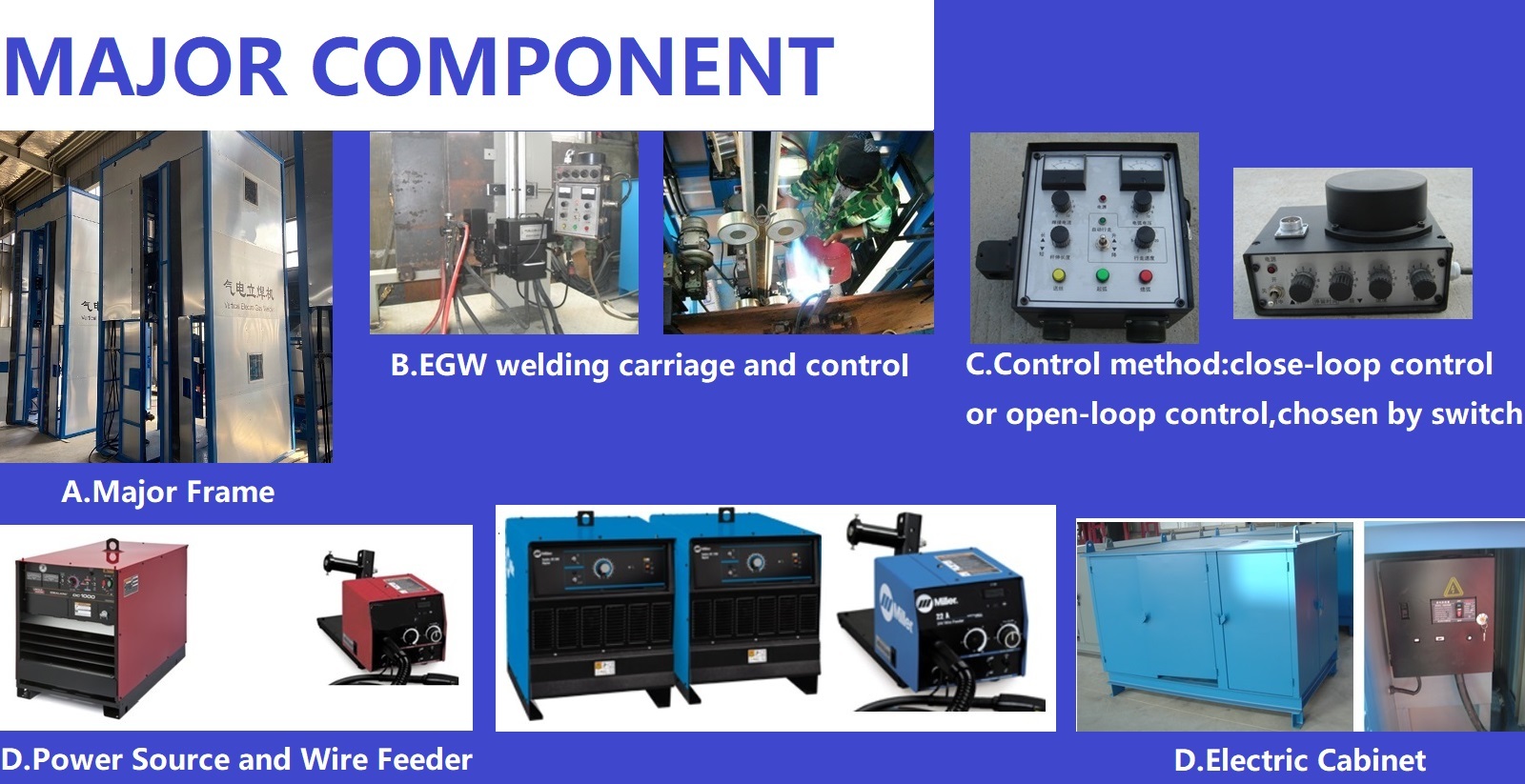

Product Introduction:

The EGW Series revolutionizes vertical welding for ultra-thick storage tanks (e.g., LNG, LPG, cryogenic vessels). Featuring dual-wire tandem EGW technology, it achieves deposition rates exceeding 25 kg/h (55 lbs/h), welding plates up to 100mm thick in a single pass. Integrated oscillation and real-time seam tracking ensure flawless fusion in critical applications requiring ASME Section VIII or API 620 compliance. Ideal for shipyards and heavy fabrication shops.

Key Specifications:

| Parameter | Specification |

|---|---|

| Welding Process | Tandem Electrogas Welding |

| Plate Thickness | 20 mm – 100 mm (0.79" – 3.94") |

| Deposition Rate | 22 – 30 kg/h (48 – 66 lbs/h) |

| Wires | 2 x 2.4 mm or 3.2 mm |

| Oscillation | ±30 mm (servo-controlled) |

| Travel Control | Laser seam tracking + Encoder feedback |

| Voltage/Current | 35–50V DC / 2x 400–750A |

| Gas System | Dual-zone gas shielding (Ar/He/CO₂) |

| Data Logging | Weld parameter recording (ISO 3834) |

| Power Supply | 480V AC, 3-Phase, 200 kVA |

Key Features:

Industry-Leading Speed: 2x productivity vs. standard EGW for thick sections.

Deep Penetration: Dual-arc synergy ensures full fusion on 100mm plates.

Active Arc Control: Independent parameter adjustment for each wire.

Zero-Defect Guarantee: Auto-correction via seam tracking & oscillation.

Remote Monitoring: Real-time weld analytics via IoT interface.

Cryogenic-Ready: Optimized for 9% Ni steel, stainless steels, and aluminum alloys.

Application Scenarios:

LNG/LPG storage tanks (API 620, Appendix Q).

Cryogenic vessels (-196°C service).

Thick-wall reactor shells in petrochemical plants.

Nuclear waste containment tanks.

Offshore platform leg sections & gravity-based structures.

|

|

Advanced EGW Vertical Seam Welding Machine for Thick-Wall Tanks Images |